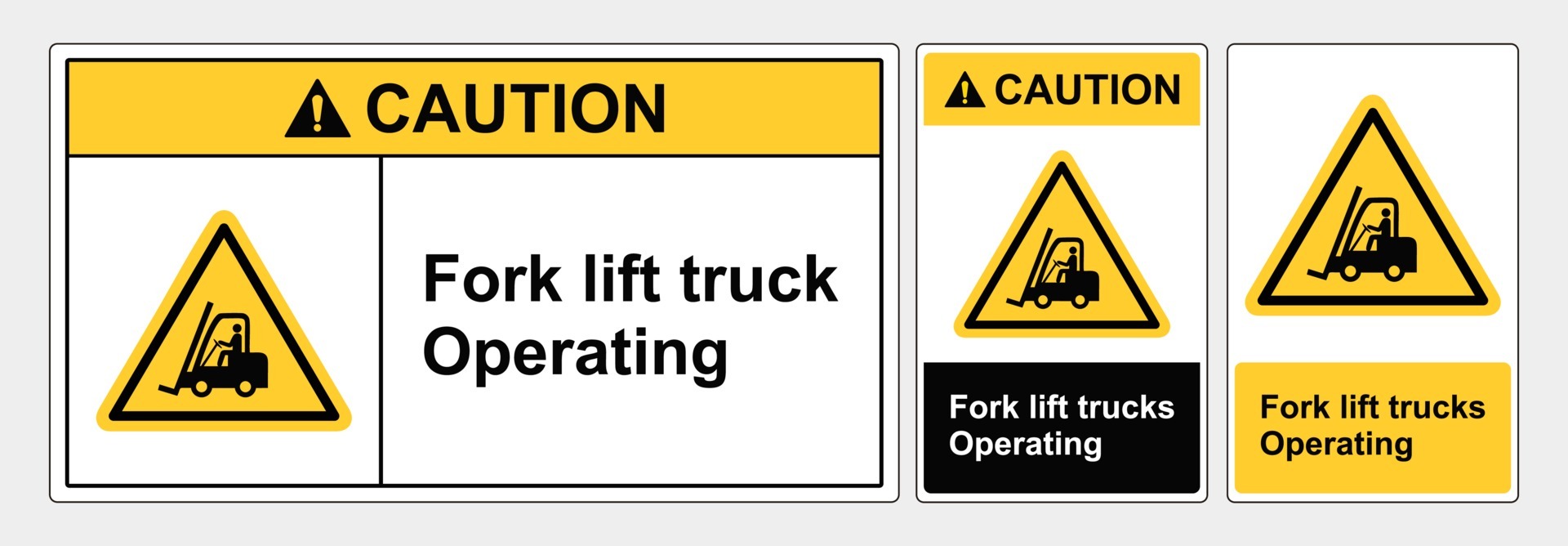

Best Practices for Displaying Forklift Truck Safety And Security Indicators in Industrial and Storage Facility Settings

The application of effective forklift truck safety signs is crucial in industrial and storage facility settings, where the threat of mishaps can dramatically affect both personnel and operations. Key considerations such as presence, placement techniques, and adherence to governing requirements are important for maximizing the effectiveness of these indicators. Additionally, the continuous upkeep and periodic analysis of signage can further enhance safety procedures - Forklift Truck Safety Signs. Nonetheless, the actual obstacle exists in balancing these elements to promote not only compliance but likewise a positive society of safety. What certain methods can organizations take on to ensure their safety and security signs genuinely offers its function?

Value of Safety And Security Signage

The significance of safety signage in settings where forklift vehicles operate can not be overstated, as these signs play a critical function in protecting against accidents and ensuring the security of workers. Effective security signage works as an important communication tool, communicating essential information about potential dangers connected with forklift operations. This consists of warnings regarding pedestrian areas, rate limits, and designated forklift paths, which are crucial for preserving an organized and risk-free workplace.

Appropriately shown safety signs can boost situational awareness among employees, reminding them of the dangers involved in their surroundings. They provide clear directions on risk-free techniques, such as putting on suitable individual safety devices (PPE) and sticking to operational guidelines. Safety and security signs adds to compliance with regulative requirements, assisting organizations avoid charges and advertise a culture of safety.

Along with their precautionary function, safety and security signs promote a feeling of liability among employees. When employees are conscious of safety and security methods and the possible effects of overlooking them, they are more probable to take proactive steps to shield themselves and their associates. As a result, spending in high-quality security signs is vital for any office where forklift vehicles are in operation.

Secret Visibility Elements

Efficient presence is critical in guaranteeing the security of both forklift operators and pedestrians in active workplace. To accomplish this, a number of key visibility variables should be thought about when creating and placing security indications.

First, the size and font style of the message on the indication play a crucial role. Bigger typefaces improve readability from a distance, allowing individuals to swiftly understand the message. Additionally, using vibrant and clear typefaces can dramatically improve clarity under numerous lights problems.

Reliable Placement Approaches

Indication positioning significantly affects their performance in connecting safety messages within forklift operations. To take full advantage of visibility and understanding, signs ought to be tactically placed in areas where forklift activity is widespread. Key places consist of intersections, blind spots, and near loading and dumping zones, where operators and pedestrians interact frequently.

Height is an additional vital element; indications ought to be put at eye level to guarantee they are conveniently seen by both forklift drivers and ground workers. Additionally, utilizing contrasting colors and clear graphics will improve exposure, especially in low-light problems or high-traffic locations.

Consider the flow of traffic when identifying placement. Indicators must be positioned to direct drivers securely and successfully through the workspace, lessening the risk of crashes. Regular assessments need to be performed to make certain that indications remain unblocked by devices or stock, as changing designs can decrease their performance.

Incorporating responses from workers pertaining to indication positioning can also bring about improvements. Engaging personnel in this straight from the source procedure cultivates a culture of safety and security and awareness, eventually adding to a more secure workplace. By applying these effective positioning approaches, companies can boost communication and adherence to safety and security protocols.

Compliance With Regulations

Making certain compliance with policies is vital for maintaining a safe workplace in forklift procedures. Governing bodies such as the Occupational Safety And Security and Health And Wellness Management (OSHA) and the American National Specification Institute (ANSI) develop standards that dictate the correct use security indications. Adherence to these policies not just advertises security yet additionally mitigates the risk of fines and lawful obligations.

Forklift security indications must be clearly noticeable, clear, and purposefully placed according to governing needs. These indicators must utilize standardized icons and color codes to convey essential details efficiently. As an example, yellow shows caution, while red signals threat, ensuring that workers can swiftly interpret the check in high-stress situations.

Organizations needs to carry out regular audits to confirm that all safety signage fulfills existing lawful requirements. Following adjustments in guidelines is additionally crucial, as non-compliance can bring about significant functional disruptions. By making sure that forklift safety signs follow mandated guidelines, business promote a society of safety recognition among staff members, therefore improving general office safety and efficiency. This dedication to conformity is an integral facet of a reliable safety administration program.

Regular Upkeep and Updates

Preserving and upgrading forklift safety and security indicators is critical for guaranteeing that they remain effective and relevant in the office. Regular evaluations ought to be performed to examine the problem of safety indicators, as direct exposure to severe industrial environments can cause fading, damage, or obsolescence. Indicators that are no more clear or that have out-of-date details can significantly weaken security protocols.

It is necessary to establish a regular upkeep timetable that includes inspecting the presence and clearness of all safety signage. Any type of indications that are put on, harmed, or misaligned ought to be without delay changed or rearranged to maintain their effectiveness. In addition, click to read more as regulations and safety criteria advance, it is essential to upgrade signage to reflect present practices and conformity demands.

Involving employees in security training sessions can likewise enhance the relevance of keeping and updating security signs. Visit This Link This not only makes sure that every person is aware of the indications' definitions however additionally fosters a society of safety within the work environment. By prioritizing regular maintenance and updates, companies can develop a safer setting and improve the overall efficacy of their forklift security signs.

Final Thought

To conclude, the execution of ideal methods for showing forklift vehicle safety indicators is necessary for improving office safety and security in industrial and warehouse environments. By prioritizing exposure, using efficient placement techniques, making certain conformity with policies, and dedicating to normal maintenance, organizations can substantially decrease the risk of accidents. Such measures not only interact risks efficiently but also cultivate a society of safety and security that profits all workers entailed in forklift procedures.

Rider Strong Then & Now!

Rider Strong Then & Now! Ross Bagley Then & Now!

Ross Bagley Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now! Jennifer Love Hewitt Then & Now!

Jennifer Love Hewitt Then & Now! Batista Then & Now!

Batista Then & Now!